Mobile Header/Navigation In Progress

Part of this work is being curious and pursuing novel ideas for using recycled materials. As we gather ideas from around the world on new applications of recycled materials, our ARMA Lab works to find opportunities to test them for Alberta conditions.

This helps make sure that what we’re doing in Alberta works for our communities and residents while advancing our circular economy for the future.

ARMA Tire Recycling Program funds 100% of the cost to produce tire-derived aggregate (TDA) and a portion of the cost to deliver the finished material to the landfill site.

This offers municipalities, First Nations and Métis Settlements, waste authorities, and commissions that order TDA for future landfill cells (up to three years before the actual cell is built) significant cost savings compared to conventional aggregate.

To acquire TDA for your next landfill cell, please email us at info@albertarecycling.ca or call our Tire Program Administrator at 1.888.999.8762.

Tire-derived aggregate (TDA) is an engineered product produced by registered and approved ARMA processors made of mechanically shredded scrap tires.

Not All TDA is Created Equal

Just specifying ‘good’ material is not enough. Quality control and quality assurance processes are still necessary to enforce specifications during production. TDA that does not meet an engineer’s specification can be rejected. ARMA will provide technical guidance if requested.

Acceptable for TDA

Unacceptable for TDA

One of Alberta's largest markets for TDA use is as a drainage material in municipal landfills, where it replaces expensive, non-renewable rock. Municipalities have benefitted from using approximately 600,000 tonnes of TDA as a drainage material in leachate collection systems. Used in nearly 200 landfill cells since 2006, this material finds additional life for over two million Alberta scrap tires per year while reducing municipalities’ costs.

TDA is frequently used in landfills across Alberta, and everyone involved in producing and using it has a vital role in delivering the best possible result.

TDA that does not meet specifications is not eligible for funding by ARMA

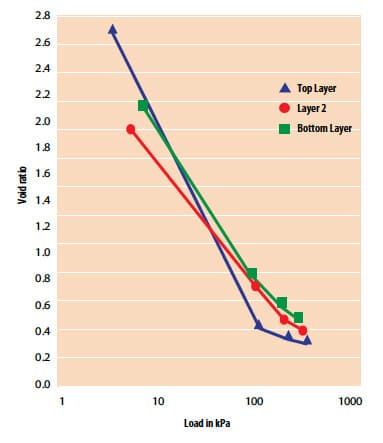

Unlike gravel, TDA leachate collection blankets compress when buried beneath waste in a landfill. Solid material gets deposited in the spaces between the TDA particles (a process known as ‘clogging’), and the more the TDA blanket is compressed, the smaller these spaces become, and the more the clogging can affect leachate drainage performance.

The testing work commissioned by ARMA investigated TDA's compression behaviour under various simulated landfill conditions using a purpose-built 1-D consolidometer. Testing results showed that the TDA spacing was still sufficient for use in a leachate collection layer, even with the reduced particle spacing.

Leachate builds above a landfill liner unless drained to a collection point and removed. One key factor controlling the amount of leachate build-up is the permeability of the leachate blanket. This is important in Alberta landfills because the amount of build-up is regulated by legislation. The testing work commissioned by ARMA investigated the permeability of TDA using a purpose-built 2-D permeameter designed specifically to accommodate TDA’s unique characteristics.

The test equipment applied vertical loads up to 300 kPa, simulating 30 to 40 m landfill heights. The testing results confirmed that the permeability of TDA compressed under a vertical load of 375 kPa remained above the target value of 10-2 m/s.

Purpose-built 2-D permeameter

Plastic liners (geomembranes) are increasingly common in landfill lining systems. While they are exceptionally effective at containing liquids, they are relatively thin and must be protected from sharp objects that can puncture them and compromise performance.

The testing commissioned by ARMA investigated the protection of geomembranes from the protruding wire of TDA particles and the edges of individual gravel particles. Different combinations of geomembranes, protective fabrics (geotextiles), and various types of TDA and gravel were used for testing. TDA particles were tested in winter conditions in a large testing frame outside a laboratory in Saskatoon. The frozen TDA particles were tested in place so the orientation of TDA particles relative to the geomembrane could be assessed.

Results confirmed that geomembrane liners should be separated from TDA and gravel particles to avoid potentially high puncture rates. Protruding wires from TDA particles were confirmed to have the potential to cause immediate geomembrane puncture. In contrast, gravel particles were confirmed to have the potential to cause excessive local strain in the underlying geomembrane.

Purpose-built large diameter TDA compression chamber

For further information on TDA, download our Final Report on TDA Hydraulic Performance and Geomembrane Damage Potential or read the final report summary in our TDA Technical Bulletin.

Download the TDA Cost Tool Spreadsheet to calculate potential cost savings by applying your expected unit rates for each input field (e.g., the thickness of the waste pile) and the aggregate cost.

To acquire TDA for your next landfill cell, please email us at info@albertarecycling.ca or call our Tire Program Administrator at 1-888-999-8762.

ARMA is partnering with stakeholders in Alberta to develop proof-of-concept rubber modified asphalt (RMA) applications in Alberta.

To foster and grow Alberta's circular economy, there is an opportunity to add value by exploring an alternative end-use for crumb rubber in the province. That’s why ARMA is exploring whether RMA could be a new outlet for recycled tire material that enhances the current conventional approach to asphalt production.

Rubber modified asphalt (RMA) is an alternative to traditional road pavement material produced by mixing crumb rubber with conventional asphalt to modify asphalt binders and mixtures. RMA was first used as a pavement material in Phoenix, Arizona, in the 1960s and is now used extensively in California, Arizona, Florida, and Texas.

As typical markets and outlets (e.g., TDA, mulch and crumb) for processed tire materials have declined and are changing, RMA could prove to be a viable market option for crumb rubber produced from Alberta scrap tires.

Between 2002 and 2007, ARMA led a pilot project that used rubber modified asphalt on roadways around the province. These projects were done in partnership with the Government of Alberta, multiple municipalities, post-secondaries, and infrastructure companies in Alberta.

This pilot provided valuable information about how RMA could be used in Alberta. Since then, RMA technology has continued to improve.

ARMA is currently collaborating with partners to explore further applications of RMA in the province, focusing on technological advancements and their relevance to our climate.